Automation That Fits Your Business

Automation That Fits Your Business

Effortless Picking.

Maximized Accuracy.

Faster Sorting.

Zero Errors.

Heavy Payloads.

Light Workload.

Smarter Control.

Seamless Coordination.

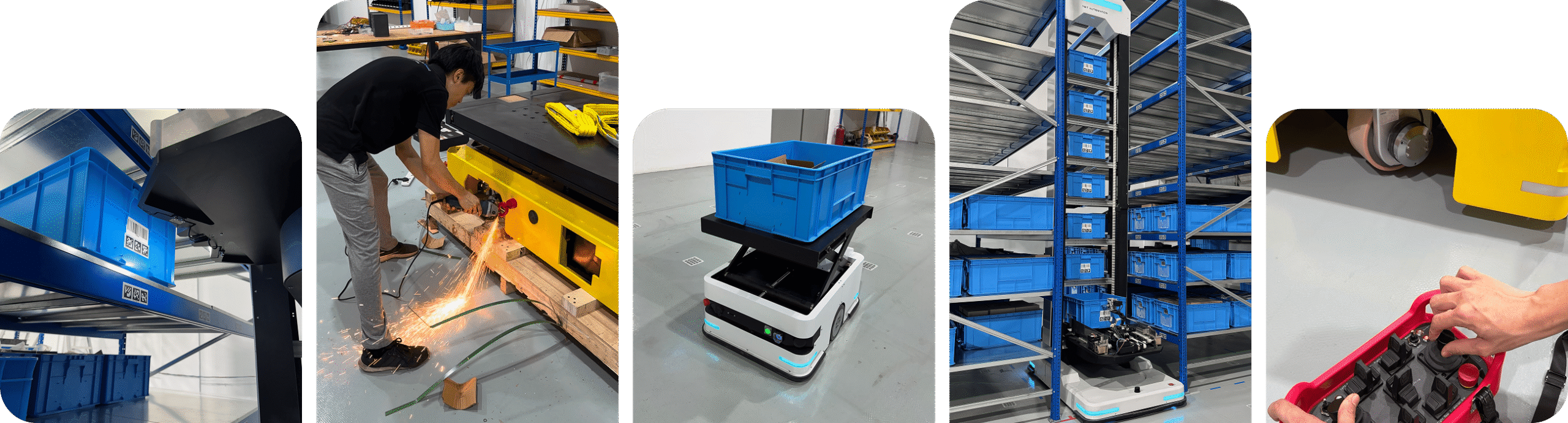

Effortless Picking.

Maximized Accuracy.

A leading fashion retailer in Malaysia sought to automate their e-commerce warehouse picking process to reduce labor costs and improve efficiency.

YDT Automation deployed its robotic picking solution using the Pick Right AGV (P3-3M) to automate tote box retrieval — enhancing order accuracy, optimizing storage utilization, and streamlining overall warehouse operations.

A third-party logistics (3PL) provider specializing in e-commerce fulfillment faced growing challenges in sorting speed, accuracy, and labor efficiency as order volumes and SKU diversity increased.

YDT Automation deployed its Sort Smart robotic sorting system, enabling the warehouse to automate operations, minimize manual errors, and scale effectively to meet rising customer demands — especially during peak seasons.

logistics

A leading fashion retailer in Malaysia faced slow manual sorting and growing order backlogs in their e-commerce warehouse. As online demand surged, their existing processes struggled to keep up with fulfillment speed and order volume.

YDT Automation implemented the Sort Smart robotic sorting system to automate their operations — enabling same-day order processing, reducing human error, and significantly improving overall warehouse efficiency.

A leading manufacturer of aircraft components in Malaysia needed a more efficient way to transport heavy mold tools through tight production spaces. To reduce manual labor and improve workplace safety, they turned to YDT Automation.

We delivered a 4-ton heavy-duty AGV with omnidirectional movement and an extendable platform, effectively solving their maneuverability challenges and streamlining daily operations.

This is the new generation of

Warehouse and Factory Automation